The lifting belt we use has a standard restriction, often people always ignore the change of the width of the ribbon in the bearing process, the change of the width of the ribbon is also a standard, the more details of the part of the more you can see whether a lifting belt manufacturer is professional. The change of ribbon width is difficult to observe with the naked eye in use. Is the lifting belt ribbon qualified? Is it up to standard? It's only clear when the sample is tested through the experiment. First of all, we should know what the standard of the width of the lifting belt is.

Lifting belt ribbon width standard: when the normal width of the ribbon is not more than 100mm, if any of the width measurement value is reduced by more than 10% of the normal width, the ribbon is judged as unqualified. Similarly, when the normal width of the ribbon is greater than 100mm, if any of the width measurements are reduced by more than 12% of the normal width, the ribbon is judged to be unqualified.Know the standard below the detailed introduction, through the seven-step experimental method that the change value of the ribbon in the case of stress.

Step 1: Install a sample of the sewing ribbon component on the test machine, without any load, so that the ribbon forms a loose catenary.

Step 2: Make an intermediate mark on the surface of the ribbon, which is perpendicular to the longitudinal axis and at the midpoint of the ribbon. A further dividing mark should be made on either side of the middle mark. The two marks should divide the braid into four equal width sections between the bearing points on both sides of the middle mark and the ribbon.

Step 3: At each mark (midpoint and two dividing marks) measure the width of the webbing to mm and record as W1.

The fourth step: then apply the bearing capacity equivalent to 2 times the limit working load on the ribbon.

Step 5: Maintain 2 times the limit working load applied force, then measure the width of the ribbon at each mark, measure the value to mm, and record as W2.

The sixth step: calculation formula. The size change of the width at the three positions is expressed by percentage, and the calculation formula is [(W2-W1)/W1] ×.

Step 7: According to the data measured in the experiment, it is easy to judge whether the lifting belt is qualified.

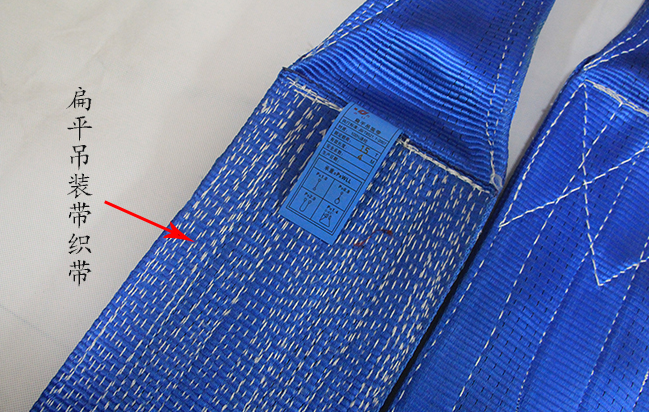

The above weaving standards and experiments are only for flat lifting belts.