Color flat lifting belt maintenance of many, many customers have not been very understand, so the new flat lifting belt use soon appeared all kinds of strange questions, resulting in hoisting belt haven't use how long, all kinds of problems occurred not only at the time of use need maintenance, including its storage, and use time bound methods need to be maintained. Some customers say back to maintenance with indifferent attitude, but the method taken is not scientific, because the color flat lifting belt and white lifting belt is by a certain difference. The product has a large tonnage and many specifications of the product, so in the maintenance of the time also need to pay attention to the place. The following comprehensive introduction.

There are many kinds of color flat lifting belt. When we choose the color lifting belt, we mainly take a fancy to the characteristics of the product with light tensile force stronger than the general polypropylene lifting belt, and the polyester material has strong wear resistance tensile force and good uv resistance. The loop part of the protective sleeve we choose is made of the same polyester material, each product has its own unique production process.

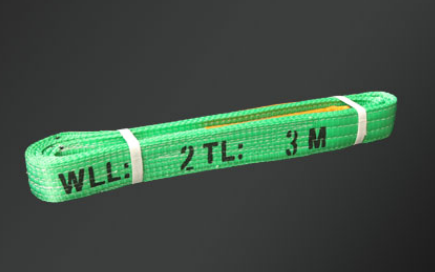

Flat lifting belts are generally divided into four categories according to their appearance: annular core piercing, annular flat, double-eye core piercing and double-eye flat. They all use the same raw materials, but also can be customized different materials, each material has a unique recipe. In the use of color flat lifting belt when the instant acceleration can not be too fast and too smooth promotion, especially in the promotion of large tonnage objects must be constant speed promotion, avoid large impact force lifting belt tear.

During transportation and storage, the colored flat lifting belt should be kept clean, avoid direct sunlight, rain and snow immersion, prevent contact with acid, alkali, oil, organic solvents and other substances, and keep away from the heating device one meter. Storage temperature between -40-100 ℃, relative humidity should be kept between 50-80%.

Color flat lifting belt must be placed in rolls in storage, can not be folded, idle period every quarter to turn over, reduce the wear of lifting belt. The conveyor belt of different types and specifications layers should not be connected together, and its joints should be glued together. The type, structure, specification and number of layers of lifting belt should be reasonably selected according to the use conditions.