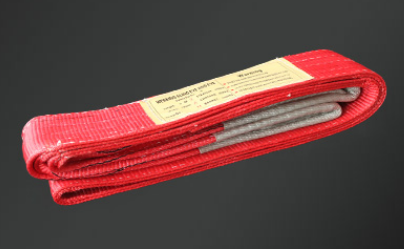

In addition to the lifting operation in the factory workshop and the construction site, the lifting belt can also be used for binding and fixing. That is to say, when the lifting target does not have stable fixing points such as hooks and rings, it is necessary to have a lifting belt for binding, and then use the slings to connect the eyes of the lifting belt to carry out the lifting operation. Most of the lifting belts used for binding are flat lifting belts.

The flat sling is more suitable for binding operation than the round sling, which is mainly related to the structure of the flat sling.

When the flat sling is used for binding, it can have a larger contact area with the lifting target. The larger the contact area is, the greater the friction will be, thus ensuring the safety of binding the flat sling with the heavy object, and effectively reducing the accidents caused by the slipping of the sling.

The contact surface between the flat sling and the lifting target is large, which can reduce the pressure between them. The reduction of pressure can effectively protect both sides, thus extending the service life of the flat sling.

The flat sling is relatively softer, which can provide excellent protection to the surface of the lifting target and prevent scratches on the surface of the lifting target.

The above is the main reason why workers often choose flat lifting belts when lifting objects.