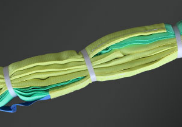

Polyester, one of the manufacturing materials for lifting belts, has many excellent properties, such as high fracture strength and elastic modulus, moderate rebound, good thermal setting, good heat and light resistance, good resistance to organic solvents, oxidants, and corrosion, and stability to weak acids, alkalis, etc.

Due to the above advantages, it has a wide range of applications in the textile and other industrial and agricultural fields. However, polyester has a symmetrical molecular structure, high crystallinity, and no highly polar groups in the structure, resulting in poor hydrophilicity, which greatly limits its comfort and dyeability.

In addition, due to its safety, non-toxic, low water absorption, and high impermeability to body fluids, polyester has been increasingly studied as a biomedical material in recent years.

However, many literature reports indicate that the low hydrophilicity structure of polyester leads to poor blood compatibility, which is also an urgent problem to be solved in the field of biomaterials.

In recent years, people have begun to study surface modification methods for polyester in order to make it more widely used and avoid weaknesses. Surface modification refers to endowing a material and its products with new surface properties, such as hydrophilicity, antistatic properties, dyeing properties, aging resistance, biocompatibility, etc., without changing the physical properties of the material and its products.

At present, the main surface modification methods for polyester include low-temperature plasma treatment, UV induced grafting, wet chemical method, ion beam irradiation, photochemical method, etc.