There are many types of electromechanical equipment, ranging from factory machinery to company printers. Advanced electromechanical equipment not only reduces labor efficiency, but also greatly improves work efficiency, helping people complete tasks that cannot be accomplished by human labor.

In some mechanical and electrical equipment production companies, workers use lifting straps to tie up and secure the equipment before using a crane for lifting. Why use lifting straps instead of other rigging equipment?

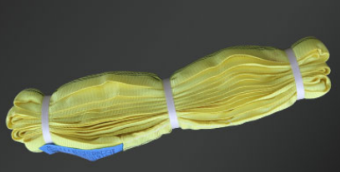

Lifting straps are a new type of lifting rigging that not only have high load-bearing capacity and are easy to use, but most importantly, they have good flexibility and will not harm the lifted object. They have a very high safety factor and are very suitable for handling mechanical and electrical equipment.

When using lifting belts to transport mechanical and electrical equipment, users must pay attention to several points: choose the appropriate lifting belt according to the tonnage of the lifted object; Crossing, twisting, knotting, and other situations are not allowed during use; When handling items with sharp edges, it is necessary to use protective sleeves, corner protectors, and other methods to protect the sling.

Regardless of the type of mechanical and electrical equipment used for handling, lifting straps must be strictly operated in accordance with regulations to avoid damage or falling of the lifted object.