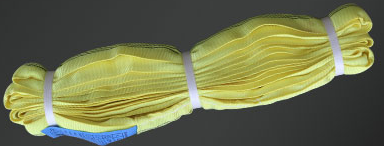

As an important rigging device for current lifting tasks, the wear and tear of lifting belts cannot be avoided during use. However, some measures can be taken to alleviate this wear and tear. While ensuring the safety of lifting operations, it can also extend the service life of lifting belts to a certain extent. So, what are the ways to alleviate the wear and tear of lifting belts during use?

Avoid friction and wear: During the lifting process, try to avoid direct contact between the lifting belt and sharp or rough surfaces to prevent wear. Using soft cushions or protective covers to protect the end of the sling is also a good choice.

Reasonable use of lifting straps: During the lifting process, try to avoid sudden stops and starts to prevent the generation of impact forces. Adjust the length and angle of the lifting belt appropriately to avoid excessive friction caused by excessive tension or improper angle.

Regular maintenance and upkeep: Regular maintenance and upkeep of lifting belts, such as cleaning, lubricating, and fastening connection parts, can extend the service life of lifting belts.

Reasonable planning of usage cycle: Lifting belts also have a service life. Reasonable planning of usage cycle can avoid long-term overload use and reduce losses.

The above solutions can to some extent alleviate the wear and tear caused by lifting operations on lifting belts. If you want to learn more about the use of common sense to alleviate the wear and tear of lifting belts, please feel free to interact with us at any time.